Exhibition Schedule *This table is scrollable

| Exhibition | Date | City, Country | Exhibition Web Site |

|---|---|---|---|

| Hydrogen & Fuel Cell Seminar | January 14-16, 2025 | Long Beach, CA, USA | https://www.fuelcellseminar.com/event/1684550e-800e-4653-b755-52fdb8aa60ea/summary |

About Hydrogen Engine

About Hydrogen Engine

- One of the main reasons why it is attracting attention as a next-generation fuel is that it is very environmentally friendly. Hydrogen does not emit CO2 when it reacts with oxygen to produce energy, emitting only steam, and so is considered to be a zero-carbon energy source, a fuel that does not emit greenhouse gases.

The power generation systems that produce energy from hydrogen include fuel cells (FC) and hydrogen internal combustion engines. Kubota is working on developing the latter — internal combustion engines.

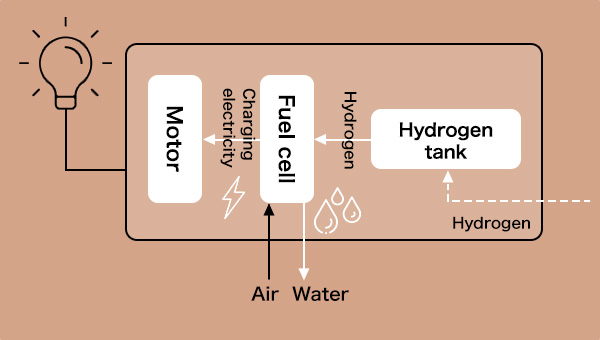

The Difference between Fuel Cells

and Hydrogen Internal Combustion Engines (HICEs)

-

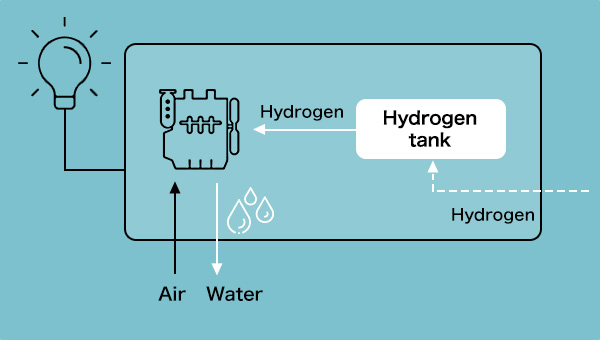

Fuel cells

- Combine hydrogen with oxygen in the air to produce the water and electricity used to power electric motors.

-

HICEs

- Power machines via internal combustion engines, which generate thermal energy by combining hydrogen with oxygen in the air, resulting in combustion explosions.

Features of Hydrogen

Internal Combustion Engines

-

Fuel Flexibility

- Hydrogen engines can also use low-purity hydrogen, allowing for reductions in fuel production costs. In addition, technologies for mixing hydrogen and natural gas can be considered, expanding fuel options. This flexibility is a significant benefit, as it allows the engines to handle a variety of fueling scenarios.

-

Existing Engine Framework

Can Be Used- When developing the hydrogen engine itself, the frame of an existing engine can be repurposed. Only parts for the fuel supply system and injection system, and the cylinder heads, etc., need to be specifically designed for hydrogen.

What are Green, Blue, and Gray Hydrogen?

When discussing hydrogen as a fuel, it is commonly classified into different categories, such as green hydrogen, blue hydrogen, and gray hydrogen.

-

- Green Hydrogen

- Green hydrogen is produced via electrolysis of water, using electricity derived from renewable energy sources, and so is considered to produce the lowest CO2 emissions.

-

- Blue Hydrogen

- Blue hydrogen is produced by breaking down fossil fuels into hydrogen and carbon dioxide, and is said to reduce CO2 emissions by capturing the carbon dioxide before it can be released into the atmosphere.

-

- Gray Hydrogen

- The process of producing gray hydrogen is similar to that of blue hydrogen, except the carbon dioxide is not captured. This is currently the prevalent form of hydrogen, but restrictions are expected to be imposed on it in the future.

Some studies show that green hydrogen and blue hydrogen could help reduce CO2 emissions by 90% or more when compared with diesel fuel,

so they are likely to attract more and more attention going forward.

Kubota’s HICEs

Kubota’s HICEs

- Kubota began selling oil-powered engines in 1922 and has since developed engines compatible with various fuels, including heavy oil, light oil, gasoline, and natural gas. We believe it is our mission to adapt Kubota's engines to new fuels. To achieve carbon neutrality through our engines, we are working on improving the fuel efficiency of industrial machinery engines and conducting research on the application of decarbonized fuels such as hydrogen, biofuels, and synthetic fuels.

-

Different Fuel, Same Footprint & PTO

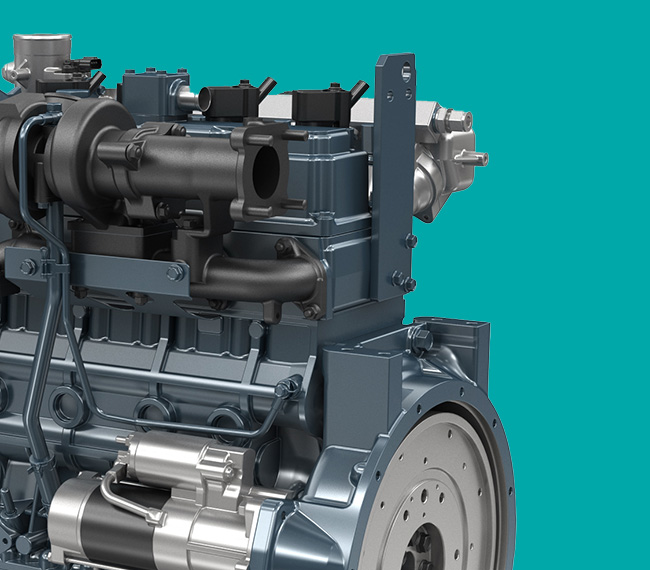

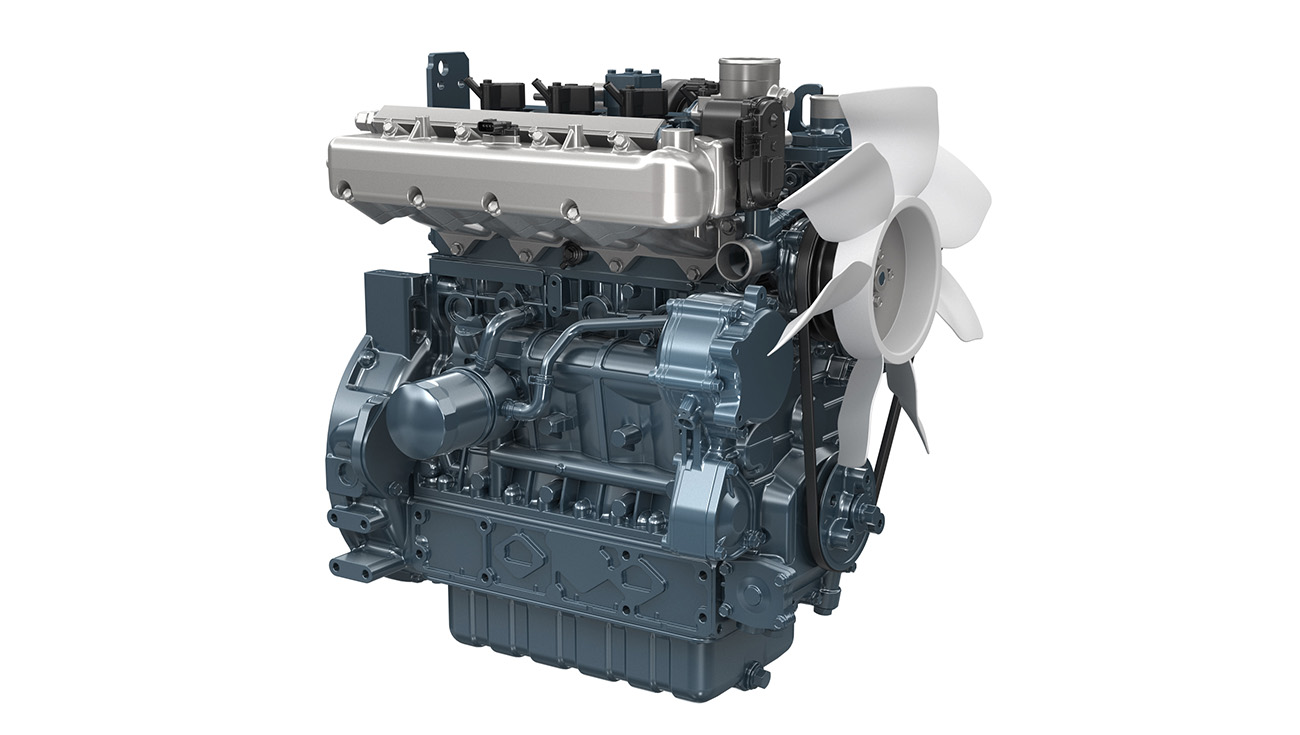

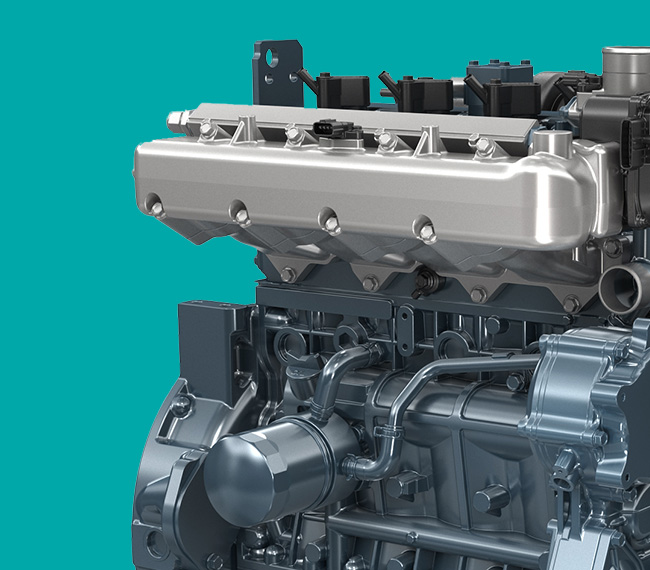

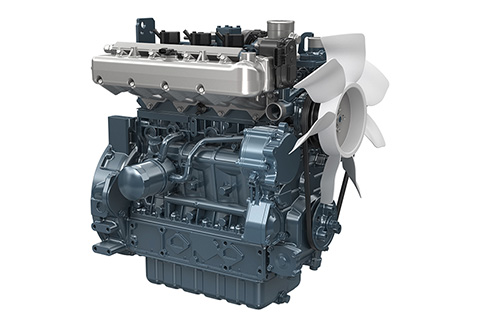

Kubota considers engines to be a solution for industrial machinery that operates in a wide range of environments, usage methods, and operating hours. In particular, the hydrogen combustion engine is developed based on the existing V3800 engine (diesel specification), ensuring compatibility for installation. Additionally, the technology of the existing spark ignition engine WG3800 is also being utilized.

Specification

Specification

- Rated output

85.0 kW @ 2600 rpm

-

Diesel Engine "V3800-CR-T"

Gasoline Engine "WG3800"

Hydrogen Engine "WG3800-H"

Features of Kubota's Hydrogen Engine

Kubota's hydrogen engine maintains the size of the existing engine and does not change the installation area, ensuring compatibility with various accessory options and customer applications. Since the engine's structural components are repurposed from the V3800, the footprint and power take-off position remain unchanged.