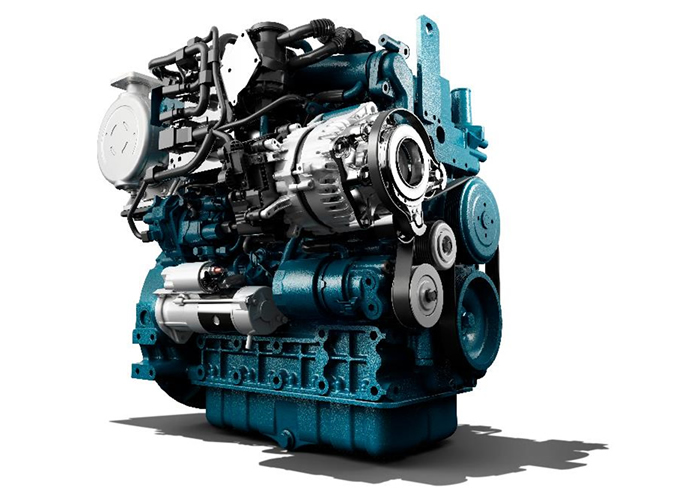

3, 2, 1... Kubota Micro Hybrid Engine

is Ready to Go!

What is the Kubota Micro Hybrid Engine?

The Kubota Micro Hybrid Engine is equipped with a 48-V motor generator and uses this electric power to compensate for high loads required instantaneously.

For some applications, high load is required for only a fraction of the total work time.

The Kubota Micro Hybrid Engine instantaneous 10-kW electric motor-assist function to match high loads allows customers to select an engine with an output power tailored to the low and medium load regions of frequent use.

In addition, applications already equipped with a Kubota engine can be converted to Micro Hybrid by installing three main components: a DC converter, a lithium-ion battery, and a motor generator. *

This allows customers to enhance the added value of their existing applications with a minimal development cost.

* Whether it can be installed depends on the Kubota engine installed and the customer's application. Please contact your Kubota engine dealer for more details.

Features of the Kubota Micro Hybrid Engine

Feature 1

Minimal Development Work — A Simple, Easy-To-Install System

The Kubota Micro Hybrid Engine has a simple design with three main components: a DC converter, a lithium-ion battery, and a motor generator attached to the existing engine model.

The Hybrid system is controlled by the engine ECU, not by signals from the vehicle. This is made possible by rewriting the software in the existing ECU of Kubota engines. No additional ECU is required for Hybrid control.

In addition, it is around the same size as common rail engines, keeping it easy to install. There is no impact on power take-off, so it can be used for existing applications or for applications currently under development.

Customers do not need to change the design of their products, and Kubota offers a package of the required peripheral components.

Feature 2

High Torque, High Response

The motor's quick response and high torque boosts work efficiency.

At low speeds, the motor provides up to 70 N⋅m of torque assistance. For example, if the motor is installed on a V3307-CR-TI engine, the maximum torque will be 400 N⋅m or greater.

Feature 3

Lower Running Costs

For example, in an application with an engine of 56kW or more due to a momentary high load, it is possible to consider replacing it with the Kubota micro hybrid engine of less than 56kW, which assists the output of 10kW with a motor. By choosing the Kubota micro hybrid engine, it will fit compactly in the mounting space because there is no aftertreatment device SCR required for diesel engines with output of 56 kW or more.

Eliminating the need for SCR saves on time needed to top up DEF. It saves maintenance work and eliminates the running cost of DEF.

In addition, the motor-assist function can also be expected to help reduce fuel consumption.

* Whether it can be installed depends on the Kubota engine installed and the customer's application.

Please contact your Kubota engine dealer for more details.